Industrial Hinges Manufacturer

At Hingelocks, we specialize in manufacturing high-quality electric cabinet hinges designed for exceptional durability and precision. Our hinges are engineered to provide secure, smooth operation for all your electrical enclosures, ensuring that your components are protected and easily accessible when needed.

Imagine the peace of mind knowing your electrical cabinets are equipped with hinges that meet the highest standards of performance and reliability. Our advanced production techniques and rigorous quality control processes guarantee that you receive only the best. Whether for high or low voltage applications, our hinges are built to withstand demanding environments and frequent use, providing long-lasting service and reducing maintenance needs.

Upgrade your electrical enclosures today with Hingelocks’ premium hinges. Contact us now to learn more about our product range and request a quote. Experience the difference in quality and reliability with Hingelocks, your trusted partner in industrial hardware solutions.

CONCEALED HINGES

FLAT MOUNTING EXPOSED HIGHES

DAMPING HINGES

CONNER HINGES

HINGES HIDDEN SCREW COVER

LIFT-OFF HIGNES

STEPPED SURFACE HINGES

SIDE DETACHABLE HINGES

Table of contents

To save you time, we have also prepared a PDF E-Catalogue containing all our fine ceramics, Just leave your email and you will get the download link immediately.

Application Industries

Special Vehicle Shipping Industry

Railway and Transportation Industries

Power distribution cabinet

Industrial Machinery and Equipment

New energy industry

Electrical System

IT Industrial Cabinet

Other Industries

What is Our Leads Time ?

Step 1: Product Design Communication (3-7 days)

Our team collaborates closely with you to understand your specific hinge and latch requirements, ensuring a tailored design that meets your needs. We focus on precision and innovation, guaranteeing products that enhance your brand’s quality and reliability.

Step 2: Latches Sampling (7-14 days)

Experience our high-quality latches firsthand with our sampling service. We provide detailed samples for thorough evaluation, allowing you to assess their fit and finish before committing to a bulk order, ensuring complete satisfaction.

Step 3: Pay The Bill (within 1 day)

Convenient and secure payment options streamline the billing process. We offer flexible terms to suit your financial needs, making it easy to finalize transactions and move forward with production without delays.

Step 4: Bulk Manufacturing (15-35 days)

Leverage our state-of-the-art manufacturing capabilities for your bulk orders. With a robust production line and stringent quality control, we ensure timely delivery of large volumes, maintaining the highest standards for hinges and latches.

Step 5: Shipping (10-15 days)

Reliable and efficient shipping solutions deliver your bulk orders promptly. We manage logistics seamlessly, ensuring your products reach you safely and on time, ready to meet your market demands.

Want to know how to compress lead times?

With just a click, unlock a world of swift solutions! Connect with our engineers effortlessly to tailor-make a speedy industrial hinges experience.

Discover Excellence with Hingelocks

With over 30 years of industry expertise, Hingelocks specialize in producing high-quality cabinet door locks, hinges, and handles for electrical switch cabinets, instrument cabinets, and network communication cabinets etc.

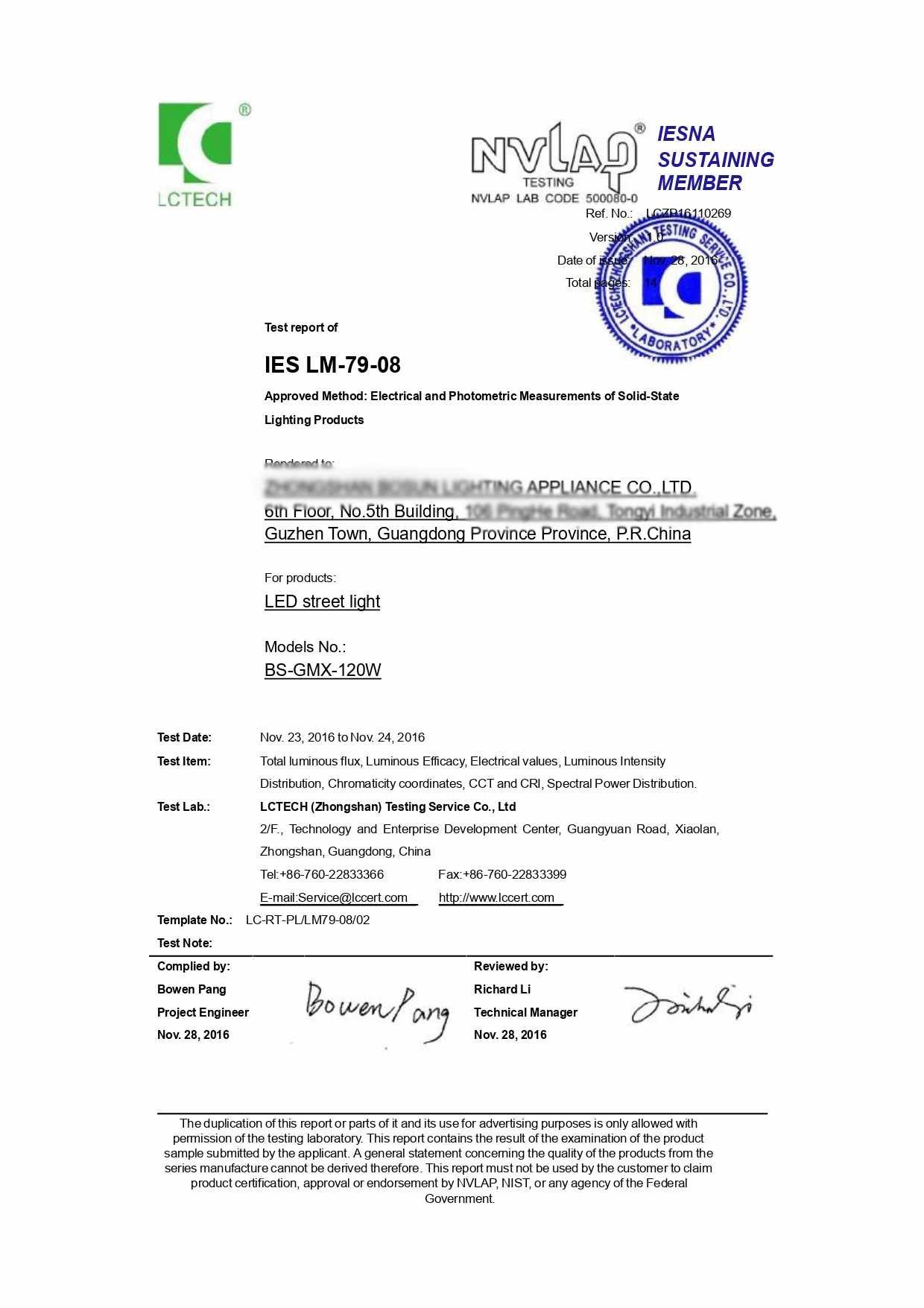

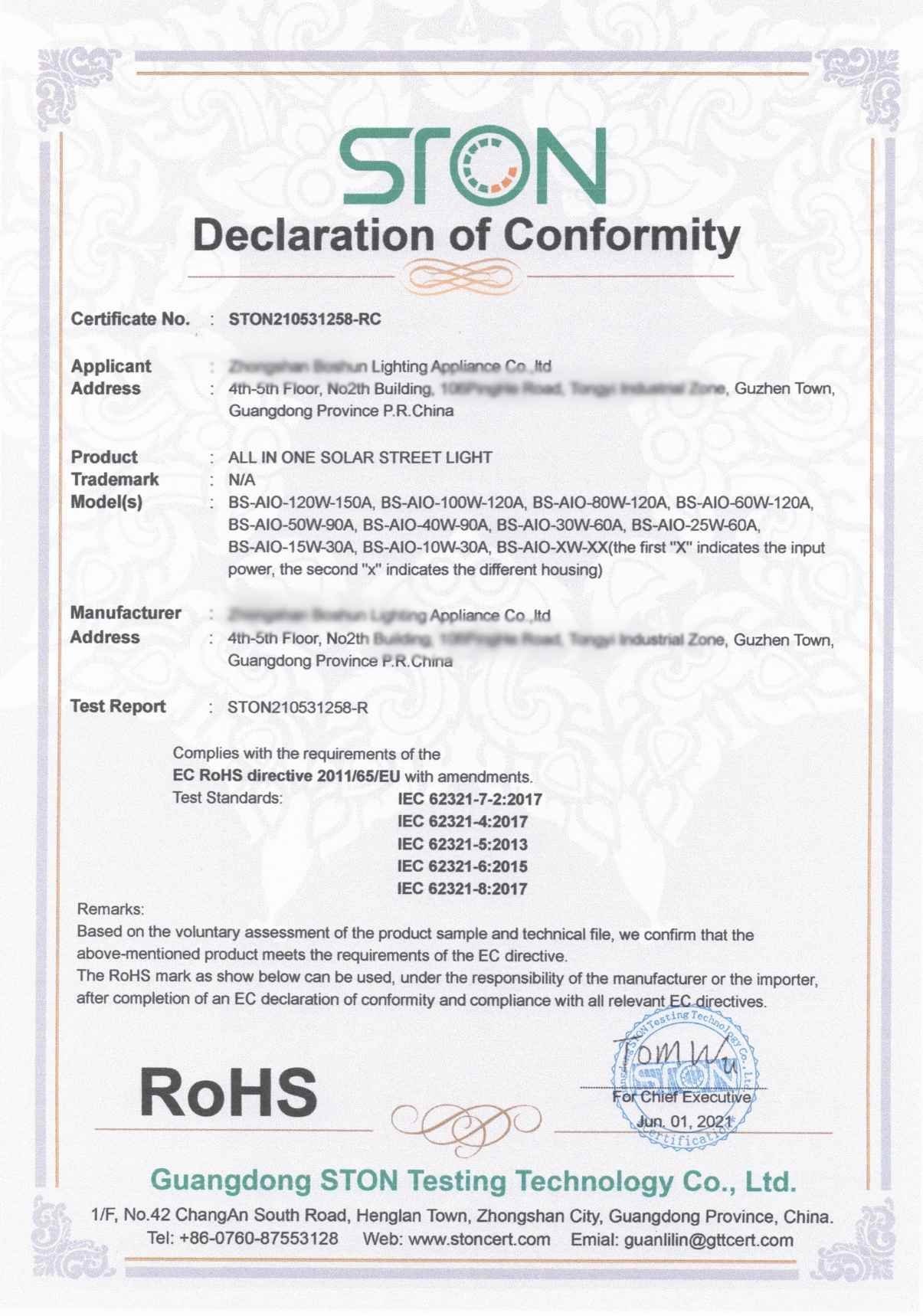

Explore our state-of-the-art facilities spanning 50,000 square meters, equipped with advanced CNC machining centers and cutting-edge casting workshops. We ensure each product meets the highest standards of quality, certified by IAPMO, CNAS, UL, and TUV.

Trusted by leading brands like TOSHIBA and Schneider, Hingelocks delivers reliability worldwide. Our commitment to sustainability includes pioneering trivalent chromium electroplating for eco-friendly manufacturing practices.

Contact Hingelocks today to discover how our expertise and dedication can elevate your industrial hardware needs. Let’s build a successful partnership together.

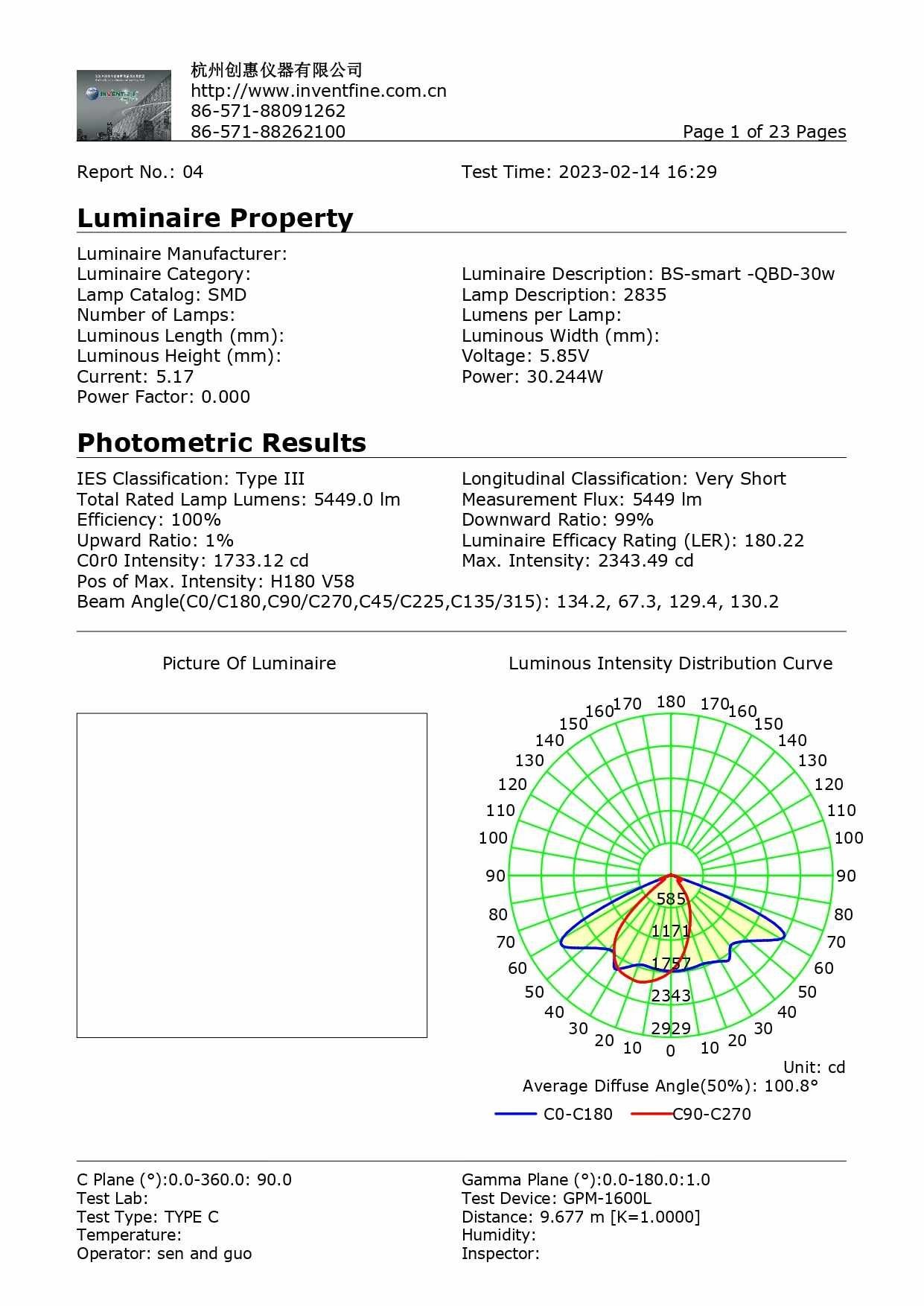

Qualtiy Control: We are Every Step of the Way

Certifications More Than ISO9001:2005

Hinglock's Creative Solutions

Free CAD Design and Samples

Unlock the potential of your product designs with Hingelocks’ free CAD design and sample services. Our expert team works closely with you to create precise CAD drawings tailored to your specifications. Experience the ease of turning your concepts into reality with complimentary samples that allow you to evaluate quality and fit before committing. This service ensures you receive exactly what you need, reducing time and cost in the development process. Partner with Hingelocks for a seamless design-to-production journey

All in-House Manufacturing

Maximize efficiency and ensure top-notch quality with Hingelocks’ all in-house manufacturing capabilities. Our state-of-the-art facility handles every aspect of production under one roof, from die-casting and machining to surface finishing and assembly. This integrated approach minimizes lead times, enhances quality control, and reduces costs, giving you a competitive edge. Trust Hingelocks to deliver consistent, high-quality products with the speed and reliability your business demands.

10 Million Products In Stock

Never face delays again with Hingelocks’ extensive inventory of over 10 million products in stock. We maintain a comprehensive range of standard parts and components, ready for immediate shipment to meet your urgent needs. Our vast stock ensures that you can swiftly respond to market demands and customer requirements without lengthy waiting periods. Count on Hingelocks for prompt, reliable supply, keeping your operations running smoothly and efficiently.

"STEPS" Quality Management System

Experience unmatched quality assurance with Hingelocks’ SOP Quality Management System. Our standardized operating procedures ensure that every product meets stringent quality criteria at each stage of production. This meticulous attention to detail guarantees the reliability and durability of our hardware solutions, providing you with peace of mind and confidence in your supply chain. Choose Hingelocks for superior quality control and consistent product excellence.

Advanced Surface Finishing Craft

Enhance the appeal and durability of your products with Hingelocks’ advanced surface finishing techniques. Our cutting-edge technology offers a wide range of finishing options, including PVD vacuum ion sputtering and nano-spraying, ensuring flawless, environmentally friendly surfaces that meet strict international standards. These premium finishes not only improve the visual appeal but also enhance the performance and longevity of your hardware. Trust Hingelocks to deliver superior surface finishes that set your products apart.

Sustainable Environmental Commitment

Align with global sustainability goals through Hingelocks’ unwavering commitment to eco-friendly practices. Our entire production process has transitioned to trivalent chromium electroplating, eliminating harmful hexavalent chromium. This shift ensures that our products are safer for both users and the environment. By choosing Hingelocks, you support responsible manufacturing practices that prioritize environmental health and safety. Partner with us for sustainable solutions that reflect your commitment to a greener future.

The Ultimate Guide

Everything Your Need to Know About Hinges

With modern technological advancements, hinge designs not only make life more convenient and comfortable but also enhance the functionality and reliability of various applications. From simple door hinges to advanced kinematic solutions like mechanical spring balance and spring assist technologies, the types and uses of hinges have become more diverse and specialized. In this article, we will explore different types of heavy-duty hinges and their applications in commercial design to help you make informed decisions.

Understanding the Importance of Door Hinges

Selecting the right door hinge is crucial not only for the smooth operation of the door but also for its durability and safety. Different door types and application scenarios require different hinges. For example, cabinet doors, interior doors, and exterior doors each need different hinge types. Hinges must handle several factors related to doors, including vertical and horizontal loads and usage frequency.

Relationship Between Frequency of Use and Door Weight

Understanding the frequency of door use helps determine whether standard or heavy-duty hinges are needed. Here is a simple guide:

| Door weight | Frequency | Hinge |

| 90kg | Medium | Standard |

| Up to 90kg | High | Heavy duty |

| 181kg | Medium | Heavy duty |

| 272kg | Low | Heavy duty |

| 453+ kg | Low | Heavy duty |

Choosing the correct hinge type can significantly improve the functionality and durability of doors.

Types of Heavy-Duty Hinges and Their Applications

The use of latches dates back to ancient times when simple mechanical devices were used to secure gates and doors. Over the centuries, the design and complexity of latches have evolved, leading to the sophisticated and highly specialized devices we use today. Modern latches are designed using advanced materials and manufacturing techniques to meet specific industry standards and requirements.

1. Counterbalance Hinges

Counterbalance hinges balance the weight of lids against gravity, reducing the effort needed to open and close them. They provide precise control and are used in applications like medical centrifuges, industrial equipment, and submarine hatches.

2. Spring-Assist Hinges

These hinges use spring mechanisms to reduce the force needed to open or close lids, commonly used in large toolboxes and light lid applications. They are also widely used in industries requiring high reliability, such as aerospace.

3. Gate Lift Assist Hinges

Designed for easy lifting of countertop pass-throughs with minimal effort, gate lift assist hinges are perfect for busy restaurants, medical facilities, and RVs.

4. Concealed Hinges

Used for applications where tamper resistance is important, concealed hinges are ideal for high-end appliances and security doors. Their compact design makes them suitable for any face frame application, offering an aesthetic appearance.

5. Pivot Hinges with Spring Assist

These hinges allow items to pivot from a single point and are used in applications like hotel Murphy beds and standard cabinet hinges in homes.

6. Adjustable Hinges

Adjustable hinges allow fine-tuning of the angle or height of heavy lids or doors without removing the hinge, suitable for applications requiring frequent adjustments.

Exterior vs. Interior Hinges

Exterior doors are typically made of metal and require thicker hinges to support their weight, while interior doors are usually made of wood and offer more variety in hinge options. Exterior door hinges must withstand outdoor conditions, making material choice crucial.

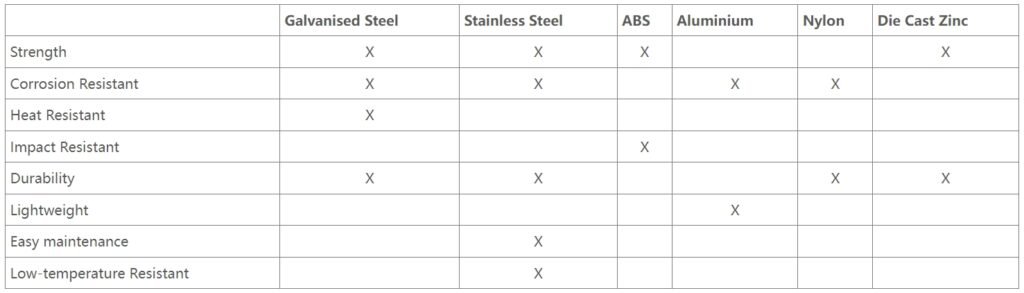

Choosing the Right Hinge Material

Choosing the right hinge type and material is essential for ensuring the longevity and high performance of doors and cabinets.

Conclusion

There is no one-size-fits-all heavy-duty hinge for every application. Understanding the characteristics and applications of different hinge types helps you make the best decisions in design and selection. Collaborating with innovative hinge manufacturers can enhance both the functionality and safety of your products. With the guidance provided in this article, you will be better equipped to choose and apply the right heavy-duty hinges to meet various commercial design needs.

Send Your Enquiry Now

Contact to Get Free Sample

What's our customer's Opinion?